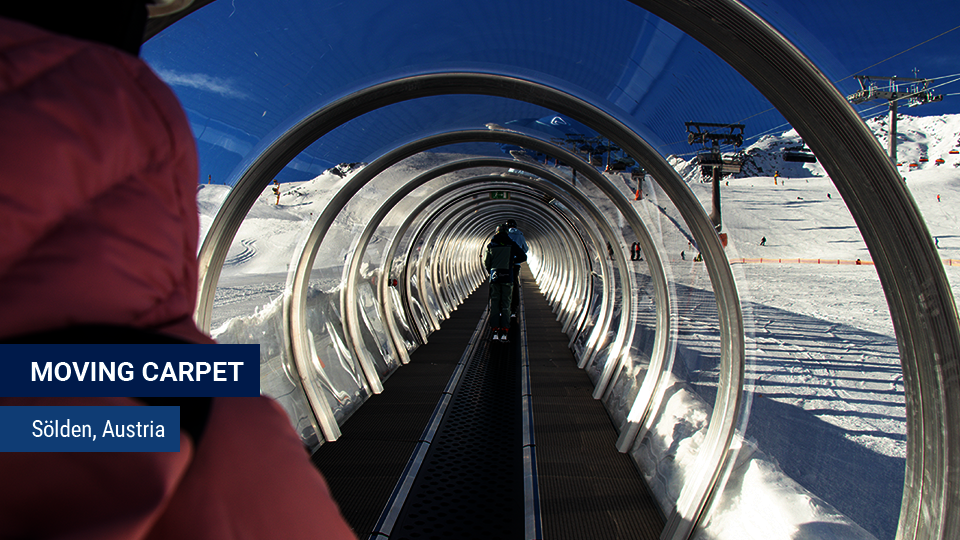

"Mini Giggijoch" Moving Carpet gives ski beginners an early start to winter

In an investment year of "superlatives" in 2025 - with a total volume of 70 million euros - Bergbahnen Sölden (Austria) built two new 8-seater chairlifts, a two-kilometre-long piste connection as well as improvements in terms of digitalization, sustainability, internationalization and regionality. A state-of-the-art Sunkid Moving Carpet, the so-called "Mini Giggijoch" conveyor belt, also went into operation in time for the 2025/2026 winter season.

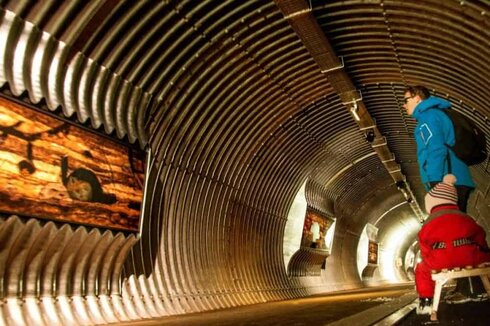

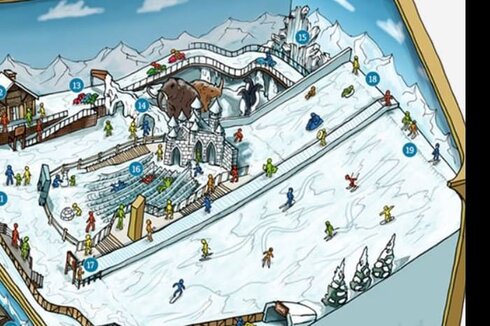

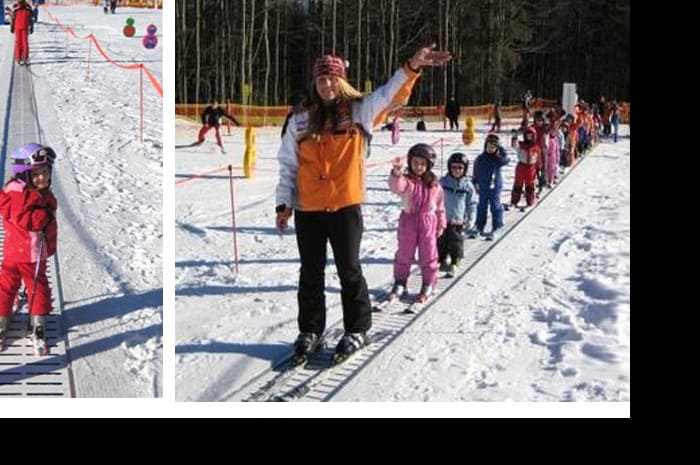

The overall design of the area around the mountain station of the Giggijoch gondola lift followed the goal of creating an "adequate infrastructure for the next generation of skiers with a modern conveyor belt and beginners' area on the Giggijoch". Sunkid marketing manager Johannes Wiedorfer saw for himself: "Especially with children, it couldn't be more uncomplicated and comfortable - thanks to the virtually seamless transport from the valley to the beginners' slope at 2,300 meters above sea level. You can get from the parking garage to the gondola without any detours. Once at the top, you are right in front of the entrance to the new conveyor belt on piste 13 - and this skiing experience is already available from mid-November."

The Giggijoch is "booming" - if you look at the conveyor capacities of the "Silberbrünnl" (new) and "Hainbachkar" lifts running parallel to the Moving Carpet (total: 6,450 people/hour according to the ski area map). In order to cope with this large number of guests, the new Sunkid conveyor belt was designed for a theoretical transport capacity of 1,800 people per hour (at a speed of 1.2 m/s). A 30 kW motor and an active-hydraulic jumbo tensioning station are used to ensure smooth operation of the system, which has an average gradient of 19%. In addition to the tried-and-tested "Blue Eye" conveyor belt, a motorized belt cleaning brush and heating mats under the drive and deflection station ensure safe ascents and freedom from ice.

The system is controlled either directly at the control box (with HMI touchscreen) under the widened exit canopy or via the external i-CONTROL terminal with 7'' display, safety stop button, start and reset switch and buzzer.

To ensure comfort for guests and operators in all weathers, the entire conveyor belt runs under an EVO-N gallery including a spacious entrance and exit canopy. Emergency exits - in the form of modern slide-up doors - and emergency stop buttons are installed every 24 meters in accordance with the standard. High-quality automatic roller shutters close the gallery after closing time and enable a quick start in the morning.

Sunkid congratulates the Bergbahnen Sölden and thanks them for the opportunity to participate in this major project: With the combination of high-performance technology, well thought-out design and a consistent focus on the needs of future generations of skiers, another milestone for a modern skiing experience has been created.